Cncsimple 2.0 is a software for easy generation of G-Code.

Briefly, I show you an example of use.

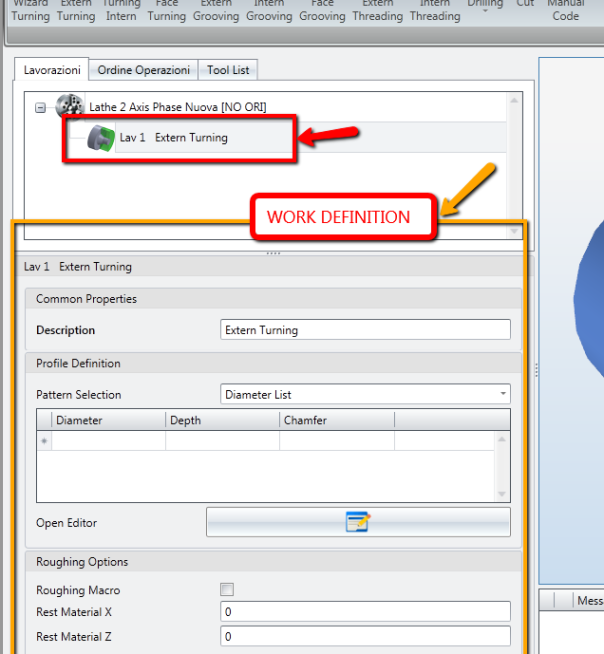

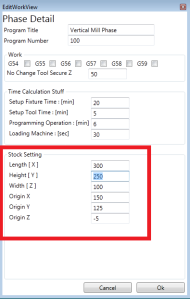

If we want to create an external turning we selected the work from toolbar.

Next the operation is added to the treeview below, when the treeview item is selected , in the space below you can insert the parameter.

Now we want to define the turning profile .

We have 2 choice , one for the simpler profile , and one for the complex profile.

For the simpler i can select [Diameter List] and inputing the diameter and the depth.

With more complex profile you can select [Profile Editor] , then click on [Open Profile Editor ]

At this point theoretically we can alredy create the G-Code but we want to check the cutting parameter.

Once the profile is defined , we want to add rest material to remove with finish tool.

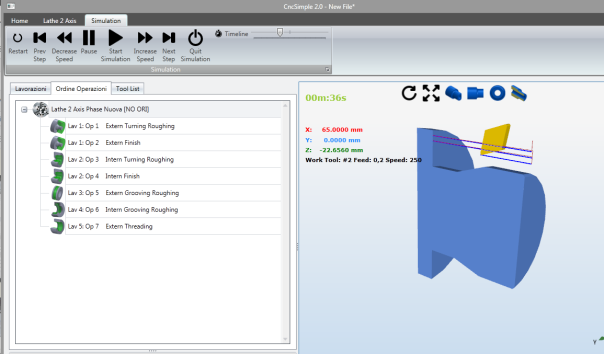

Next we move to next tab to check the generated operation.

If we have setted the rest material now we have 2 operation , roughing and finish ,otherwise we have only roughing operation.

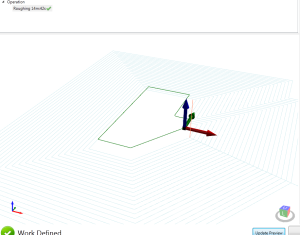

When we selected an operation from the treeview we can alredy see the toolpath on the screen. The tool parameter are alredy stored in a database , of course we can update them.

In the next tab we can see the operation grouped by the used tool.

This view make sense when you use the same tool for multiple operation and you want to change the cutting data only once for all operation.

If we want to change the stock material we can change the material from field showed below . All the parameter will be update to the new material.

Finally we can see the back plotting of toolpath .

Selected the operation you want to simulate, next select the tab [Simulation] from the Menu and press Start.

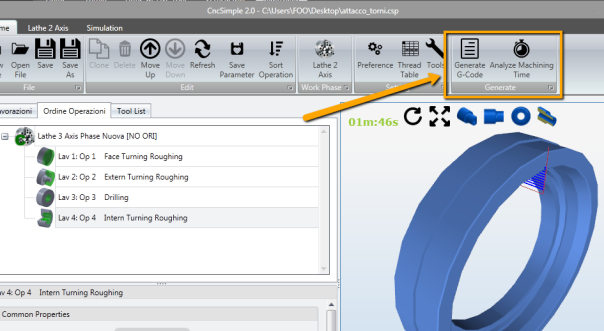

Now for the machine time summary press the [Analyze Machining Time] on the toolbar.

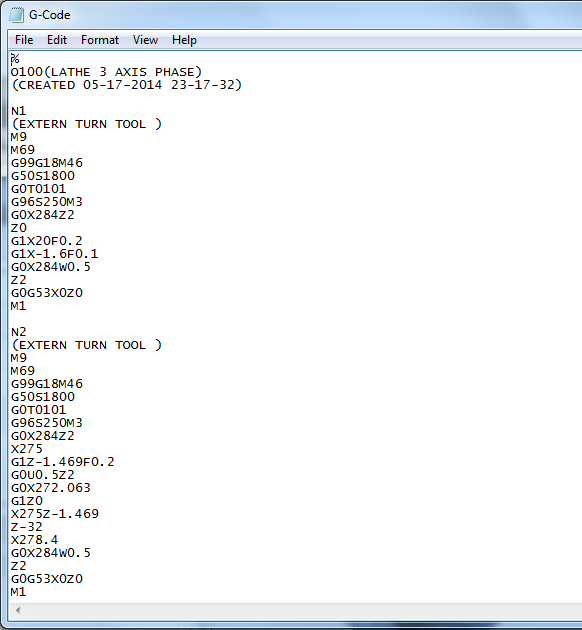

And to obtain the code press [Generate Code] button.

If you have any question mail me to cncsimple@gmail.com

Thanks.